Salt Lake’s Best head Gasket Repair Shop

At Pyle Automotive, our ASE certified mechanics are head gasket repair experts. We have the experience with all makes & models to quickly diagnose & repair your car. Call Pyle today & have us take a look!

Fast, Affordable Head Gasket Repair & Replacement

A blown head gasket is typically the result of your engine overheating. Overheating can cause head gasket to fail through leakage by either cracking the head gasket’s casing or causing erosion over time. There are a number of indications you have a blown head gasket. Here are a few common indications that your head gasket is bad:

White Smoke From The Tailpipe

Milky White Coloration In The Oil

Unexplained Coolant Lost, No Leaks

Bubbling In The Radiator & Coolant Reservoir

Engine Quickly Overheating

Significant Loss Of Engine Power

If you are experiencing any of these issues, please give us a quick call for a repair estimate.

Why You Can Count On Pyle Auto

For Over 75 Years Pyle Automotive has be serving Salt Lake City with quality auto repairs & a great experience.

ASE Certified Mechanics

Our mechanics work on all makes & models.

Fast, Affordable Head Gasket Repairs

We accurately diagnose the issues and ret the repairs done right!

5-Star Customer Experience

As a locally owned & operated shop, our friendly staff and expert mechanics look forward to helping you!

Standard Parts & Labor Warranty

What You Can Expect From Pyle Automotive

Pyle Automotive provides quality repairs and services. Contact us today at (801) 467-7455, and we will be happy to answer any questions regarding our head gasket services.

Expert Mechanics, All Makes & Models

Prompt, Friendly Service

12 Month/12,000 Mile Warranty On Parts & Labor

Have A Question For Us?

Our Happy Customers

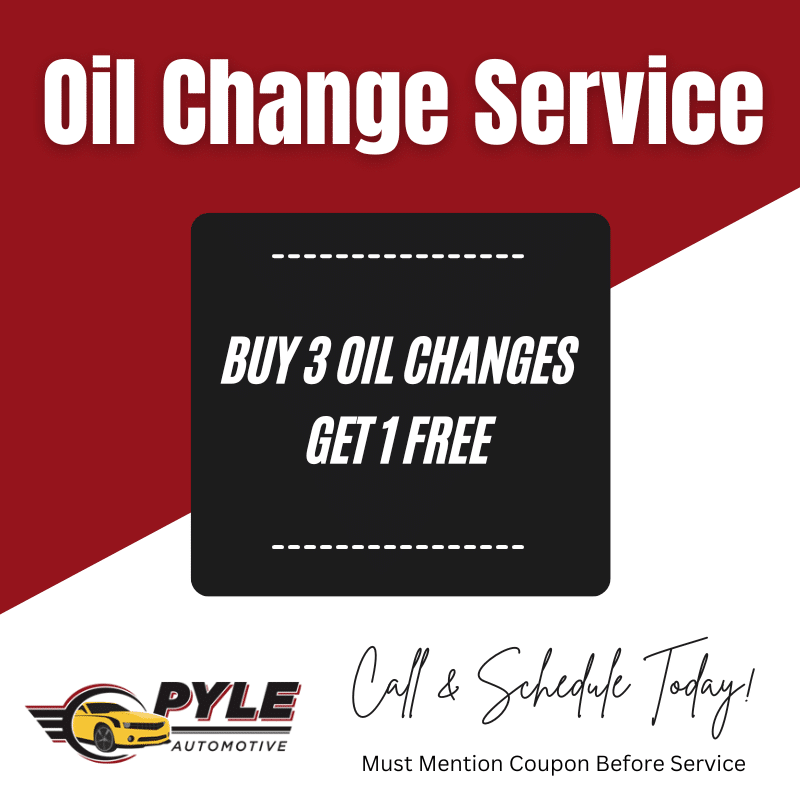

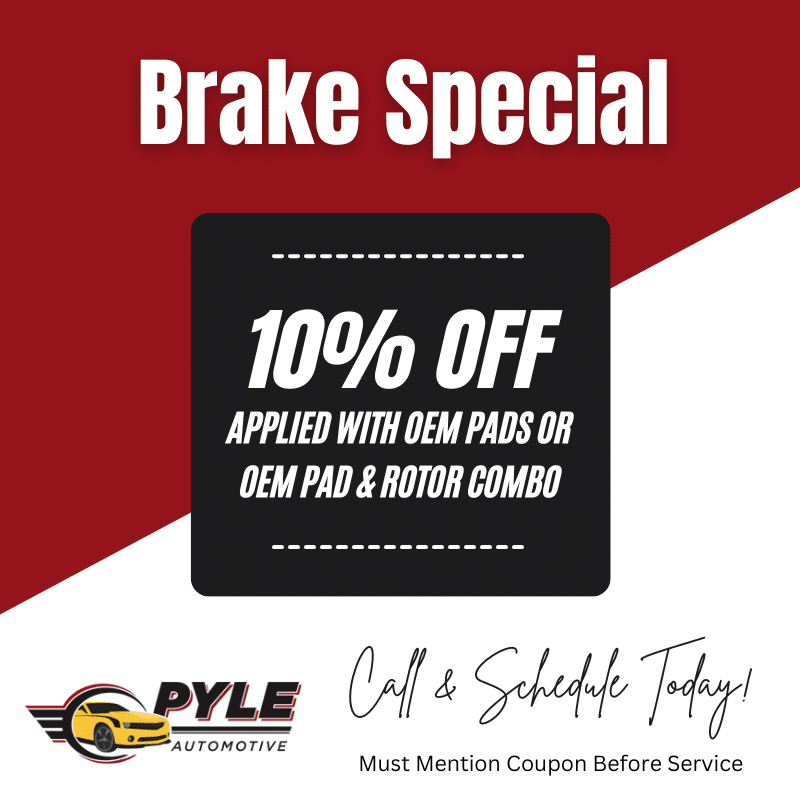

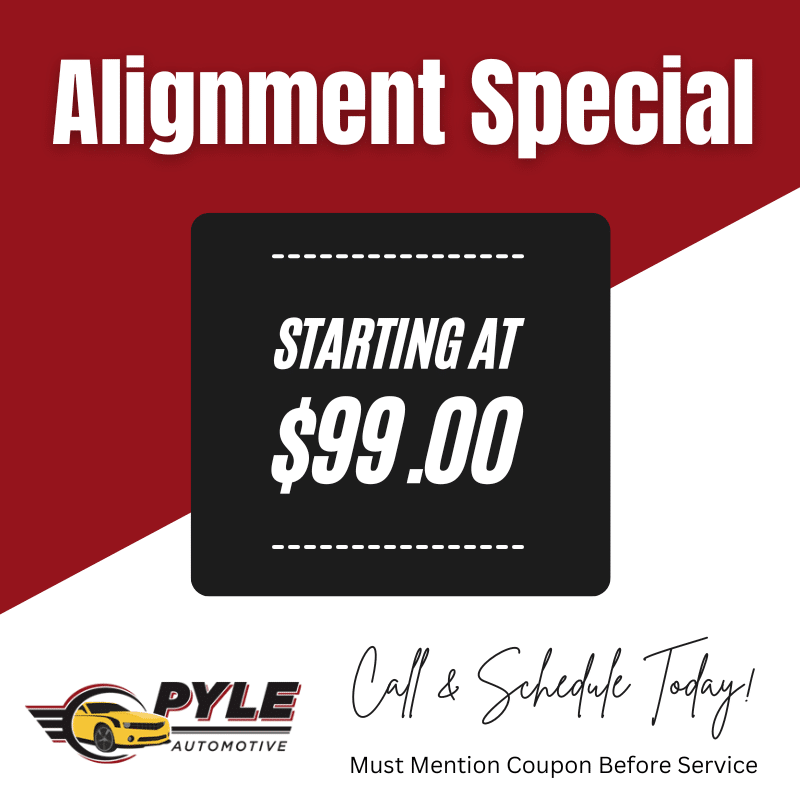

Current Specials & Offers

Faq’s

It’s important to take care of problems with your vehicle right away. To make it easier for you to take care of your vehicle and to avoid problems, here are the answers to our most frequently asked questions. If you can’t find what you’re looking for, please contact us today.

Can an overheating motor cause a head gasket failure?

Yes, one of the primary causes of head gasket failure is engine overheating. When the engine temperature escalates beyond normal levels, the cylinder head can undergo expansion to a degree where it results in the compression of the head gasket. This usually occurs between the cylinders, as this is the most vulnerable point due to its thinness. Consequently, the extruded material or the compromised combustion armor establishes a leakage path, accommodating coolant and/or combustion gases. This phenomenon causes the head gasket to fail, leading to significant engine problems if not addressed promptly.

Can engine knock cause a head gasket to fail?

Detonation, or spark knock, is a significant cause of head gasket failure, resulting from severe spikes in combustion chamber pressure. Over time, these pressure surges can overpower and fracture the gasket armor surrounding the cylinder, leading to burn through and subsequent compression loss. Detonation may be caused by several issues, the most common of which is the buildup of carbon in the combustion chamber, increasing compression. Many modern engines operate at relatively high compression ratios, and some even require high octane fuel. If the compression level rises to a point where the fuel spontaneously combusts before the spark can ignite it, the engine will produce a knocking or pinging sound under load, indicating a problem.

Why are some vehicles more prone to head gasket failure?

In bi-metallic engines, sealing problems pose a significant challenge due to the differential expansion rates of aluminum cylinder heads and cast-iron cylinder blocks during the warm-up cycle. The aluminum cylinder heads tend to heat faster than the cast-iron cylinder blocks, further exacerbating the disparity in expansion rates. This discrepancy leads to a “scrubbing” effect, which gradually results in the deterioration of the stainless steel “fire ring” that prevents combustion gases from permeating into the cooling system. Consequently, the repeated thermal events cumulatively result in the failure of cylinder head gaskets. To counteract this issue, numerous aftermarket gasket manufacturers have pioneered the development of head gaskets utilizing materials derived from space-age technology, which exhibit increased resistivity against scuffing wear in bi-metallic applications.